Essential Guide to Sourcing Quality Vacuum Components

Maintaining and repairing vacuum systems across various industries requires access to reliable replacement parts. Whether you're managing industrial vacuum equipment, laboratory systems, or commercial cleaning machinery, finding the right vacuum replacement parts is crucial for optimal performance and longevity. This comprehensive guide will explore the various aspects of sourcing quality components, understanding market applications, and ensuring compatibility across different vacuum systems.

Understanding Vacuum System Components

Common Vacuum Replacement Parts

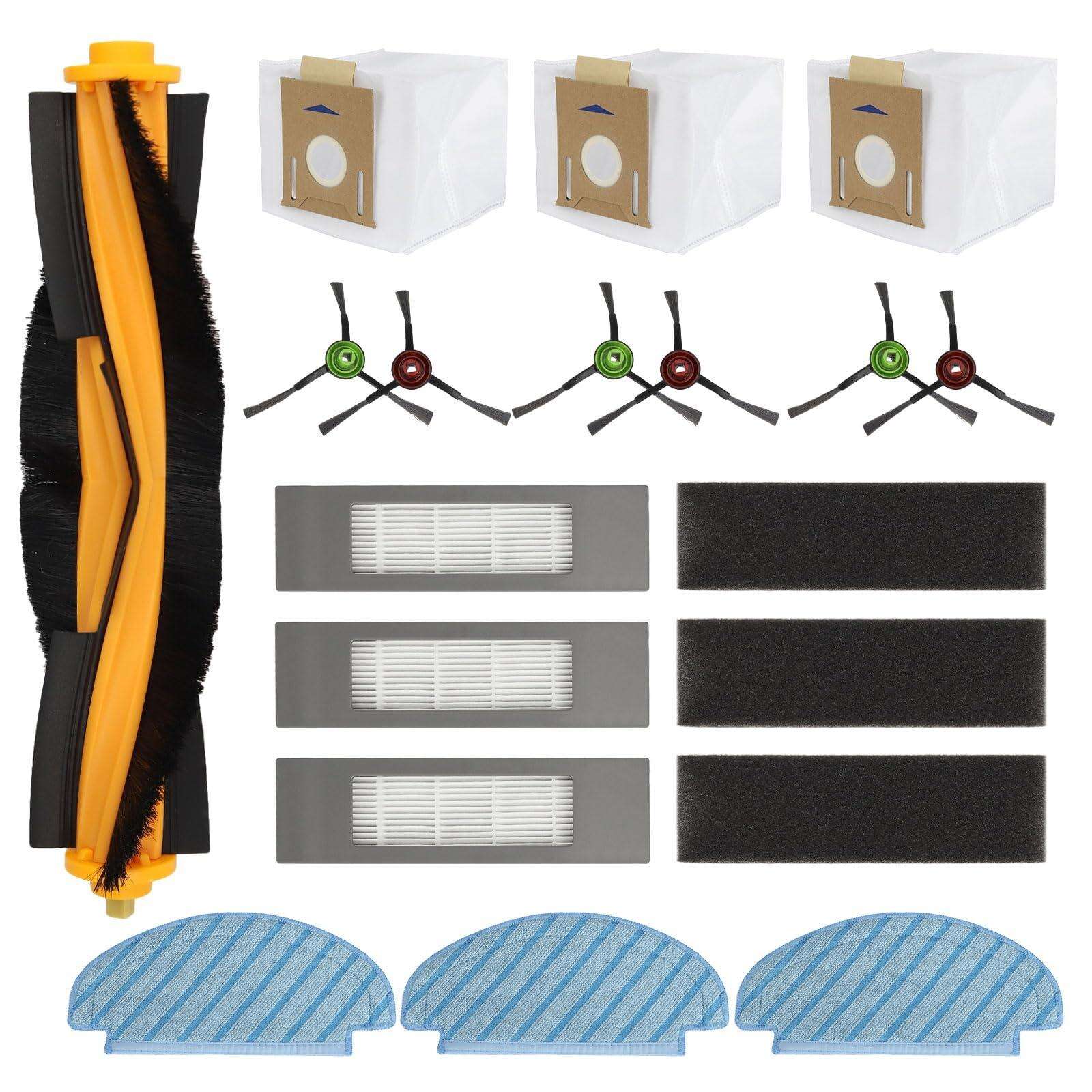

Vacuum systems consist of multiple components that may require periodic replacement. These include seals, gaskets, filters, pumps, motors, and various mechanical parts. Each component plays a vital role in maintaining proper vacuum levels and system efficiency. Understanding these parts' functions helps in making informed decisions when sourcing replacements.

The quality of vacuum replacement parts directly impacts system performance and reliability. High-quality components often feature superior materials, precise manufacturing tolerances, and better durability. While premium parts may cost more initially, they typically offer better value through extended service life and improved system efficiency.

Industry-Specific Requirements

Different industries have unique requirements for vacuum replacement parts. Medical and pharmaceutical applications demand components that meet strict sanitary standards and regulatory compliance. Industrial manufacturing may require parts capable of withstanding harsh environments and continuous operation. Laboratory applications often need ultra-clean components that maintain precise vacuum levels.

Understanding these specific requirements ensures proper component selection and compliance with industry standards. It's essential to consider factors such as temperature resistance, chemical compatibility, and pressure ratings when choosing replacement parts for specific applications.

Sourcing Strategies for Different Applications

Manufacturing and Industrial Solutions

Industrial vacuum systems often require robust replacement parts designed for heavy-duty use. When sourcing components for manufacturing applications, focus on durability, reliability, and compatibility with existing systems. Working with established suppliers who understand industrial requirements helps ensure access to appropriate parts and technical support.

Many manufacturers offer customized vacuum replacement parts for specific industrial applications. These specialized components often provide better performance and longevity compared to generic alternatives. Consider working with suppliers who can provide documentation of material specifications and performance testing.

Laboratory and Research Equipment

Research facilities and laboratories require precision vacuum components that maintain system integrity. When sourcing parts for these applications, emphasis should be placed on cleanliness, accuracy, and compatibility with sensitive equipment. Suppliers should provide detailed specifications and certification for critical components.

Documentation and traceability are particularly important for laboratory applications. Choose suppliers who maintain detailed records and can provide certificates of conformity when required. This ensures compliance with laboratory standards and facilitates quality control procedures.

Evaluating Supplier Capabilities

Quality Assurance Standards

Reliable suppliers maintain strict quality control processes for vacuum replacement parts. Look for vendors who follow established quality management systems and industry standards. This includes regular testing, documentation, and traceability of components.

Consider suppliers who provide comprehensive technical documentation and support services. This includes access to detailed specifications, installation guides, and troubleshooting assistance. Quality suppliers often offer warranty coverage and after-sales support for their components.

Technical Support and Expertise

Expert technical support is invaluable when sourcing vacuum replacement parts. Choose suppliers who demonstrate thorough knowledge of vacuum technology and applications. This expertise helps ensure proper component selection and compatibility with existing systems.

Look for suppliers who offer consultation services and can assist with system optimization. This might include recommendations for preventive maintenance, system upgrades, or performance improvements through component selection.

Cost Considerations and Value Analysis

Total Cost of Ownership

When evaluating vacuum replacement parts, consider the total cost of ownership rather than just the initial purchase price. This includes factors such as expected service life, maintenance requirements, and system efficiency impacts. Higher-quality components often provide better value through reduced maintenance needs and longer service intervals.

Calculate the long-term cost implications of different component options. Consider factors such as installation time, potential downtime, and maintenance requirements. This analysis helps justify investment in quality components that offer better reliability and performance.

Inventory Management Strategies

Effective inventory management of vacuum replacement parts helps minimize downtime and maintenance costs. Develop relationships with reliable suppliers who can provide consistent availability and quick delivery of critical components. Consider stocking commonly needed parts while balancing inventory costs with operational requirements.

Implement a systematic approach to tracking part usage and replacement intervals. This data helps optimize inventory levels and predict maintenance needs. Work with suppliers who offer inventory management solutions and can provide regular supply chain updates.

Frequently Asked Questions

How can I ensure compatibility when ordering vacuum replacement parts?

To ensure compatibility, always verify the exact model and specifications of your vacuum system. Consult the original equipment documentation and work with suppliers who can cross-reference part numbers. When possible, provide the supplier with detailed system information including manufacturer, model number, and specific application requirements.

What documentation should I expect from quality vacuum part suppliers?

Quality suppliers should provide detailed technical specifications, material certificates, testing documentation, and warranty information. For critical applications, expect certificates of conformity and material traceability documents. Installation guides and maintenance recommendations should also be available.

How often should vacuum system components be replaced?

Replacement intervals vary depending on the component type, usage patterns, and operating conditions. Regular system monitoring and maintenance inspections help determine optimal replacement timing. Follow manufacturer recommendations and maintain detailed service records to establish appropriate replacement schedules for your specific application.

What factors impact the cost of vacuum replacement parts?

Several factors influence component costs, including material quality, manufacturing precision, certification requirements, and order quantity. Specialized or custom parts typically cost more than standard components. Consider the total cost of ownership, including installation, maintenance, and potential impact on system performance when evaluating different options.