The global demand for robot vacuum cleaners continues to surge, creating unprecedented opportunities for importers seeking to capitalize on this expanding market. However, success in this competitive landscape hinges on understanding which robot vacuum parts deliver the most reliable performance over extended periods. For importers, identifying high-quality components that minimize warranty claims and customer complaints while maximizing profit margins represents a critical business decision that can determine long-term market success.

Modern robotic cleaning systems incorporate dozens of precision-engineered components, each playing a vital role in overall performance and durability. Understanding the reliability characteristics of different parts enables importers to make informed sourcing decisions, negotiate better terms with manufacturers, and build sustainable business relationships with retailers and consumers. The key lies in recognizing which components are most susceptible to wear and which deliver consistent performance across various cleaning environments.

Essential Motor Components and Drive Systems

Brushless DC Motors for Suction Performance

The heart of any robot vacuum lies in its motor system, with brushless DC motors representing the gold standard for long-term reliability. These motors eliminate the friction and wear associated with traditional brushed designs, resulting in significantly extended operational lifespans. Quality brushless motors can operate for thousands of hours without performance degradation, making them an excellent investment for importers focused on building reputation for reliable products.

High-grade brushless motors feature precision-balanced rotors, advanced bearing systems, and sophisticated electronic speed control circuits. These components work together to deliver consistent suction power while minimizing noise levels and energy consumption. Importers should prioritize suppliers who provide detailed motor specifications, including torque ratings, efficiency curves, and expected operational lifespans under various load conditions.

Wheel Drive Mechanisms and Encoders

The mobility system represents another critical area where component quality directly impacts long-term reliability. Premium wheel drive assemblies incorporate sealed bearings, corrosion-resistant materials, and precision-machined gears that maintain accurate positioning over extended use periods. These systems must withstand constant direction changes, varying floor surfaces, and occasional impacts with furniture or obstacles.

Optical encoders within the drive system provide essential position feedback for navigation algorithms. High-quality encoders feature dust-resistant housings and stable optical sensors that maintain accuracy even in challenging environments. Importers should verify that drive systems include adequate protection against hair and debris infiltration, as these contaminants represent the primary cause of premature failure in mobility components.

Filtration Systems and Air Path Engineering

HEPA Filter Construction and Longevity

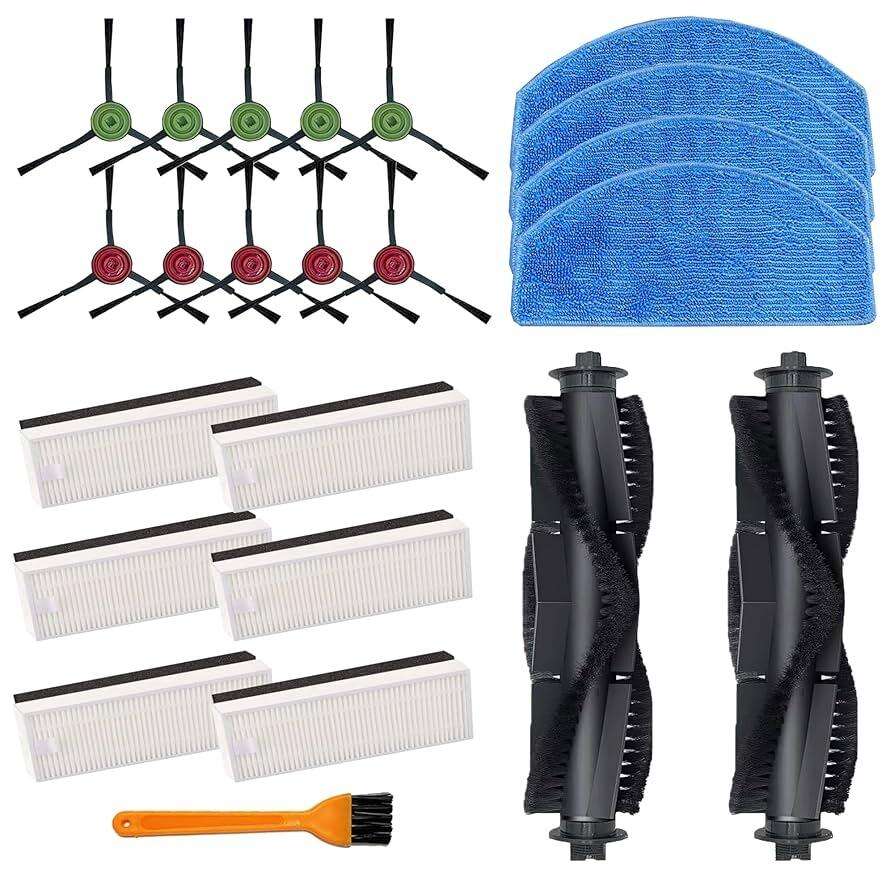

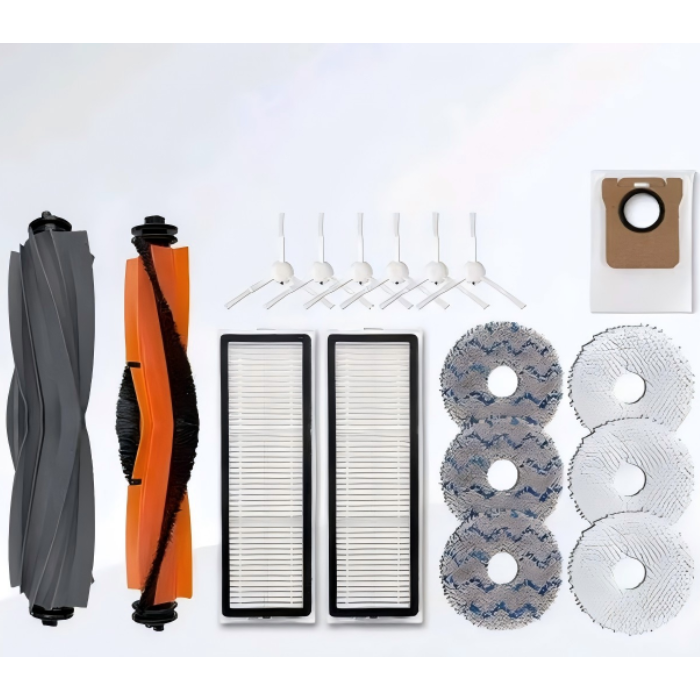

Advanced filtration systems play a crucial role in both cleaning performance and component longevity throughout the robot vacuum. Premium HEPA filters utilize multi-layer construction with progressively finer filtration stages, ensuring optimal particle capture while maintaining adequate airflow. The filter housing design significantly impacts both filtration efficiency and ease of maintenance, directly affecting customer satisfaction and warranty claim rates.

Quality HEPA filters feature reinforced frames, sealed edges, and moisture-resistant materials that prevent degradation in humid environments. These filters maintain their structural integrity through multiple cleaning cycles, reducing replacement frequency and associated customer service costs. Importers should evaluate filter suppliers based on their ability to provide consistent quality across large production runs while meeting international air filtration standards.

Dust Collection Chamber Design

The dust collection chamber represents a critical interface between mechanical components and collected debris. Well-engineered chambers incorporate smooth internal surfaces, strategic air flow patterns, and secure sealing mechanisms that prevent dust leakage during operation. The chamber design must accommodate easy removal and cleaning while maintaining structural integrity through repeated use cycles.

Premium dust chambers feature antimicrobial coatings and materials that resist odor retention and bacterial growth. These characteristics become increasingly important as consumers demand hygienic cleaning solutions for their homes. Importers should prioritize suppliers who can demonstrate comprehensive testing of chamber materials under various debris conditions, including pet hair, fine dust, and organic matter.

Navigation and Sensor Technology

LiDAR Systems and Optical Sensors

Modern robot vacuum parts increasingly incorporate sophisticated navigation systems that rely on multiple sensor technologies working in coordination. LiDAR systems provide precise distance measurements and environmental mapping capabilities, enabling efficient cleaning patterns and obstacle avoidance. The reliability of these sensors directly impacts the robot's ability to navigate complex home environments without human intervention.

Quality LiDAR assemblies feature sealed optical chambers, calibrated laser diodes, and precision rotating mechanisms that maintain accuracy over extended operational periods. These systems must withstand vibration, temperature variations, and occasional physical impacts while continuing to provide reliable navigation data. Importers should evaluate LiDAR suppliers based on their track record of consistent performance across diverse environmental conditions.

Cliff Detection and Proximity Sensors

Safety sensors represent critical components that prevent damage to both the robot vacuum and surrounding property. Cliff detection sensors utilize infrared technology to identify drop-offs and prevent falls down stairs or off elevated surfaces. These sensors must maintain reliable operation across various floor types, lighting conditions, and surface reflectivity characteristics.

Proximity sensors complement the navigation system by detecting nearby obstacles and enabling gentle contact with furniture and walls. High-quality sensors feature adjustable sensitivity settings, robust housings, and reliable signal processing circuits that minimize false readings. Importers should verify that sensor systems include comprehensive self-diagnostic capabilities that alert users to potential maintenance needs before failures occur.

Cleaning Mechanism Components

Roller Brush Systems and Materials

The cleaning effectiveness of robot vacuums depends heavily on the design and construction of roller brush assemblies. Premium brushes incorporate multiple bristle types, optimized spacing patterns, and durable mounting systems that maintain effectiveness through thousands of cleaning cycles. The brush materials must resist wear from abrasive debris while maintaining flexibility for effective carpet cleaning.

Advanced roller brush designs feature anti-tangle geometries that reduce hair wrap and minimize maintenance requirements. These systems incorporate removable brush rolls, tool-free disassembly mechanisms, and clear maintenance indicators that enhance user experience. Importers should prioritize brush systems that demonstrate consistent performance across various debris types and floor surfaces while minimizing customer support requirements.

Side Brush Assemblies and Edge Cleaning

Side brush systems extend the robot's cleaning reach into corners and along wall edges where the main roller cannot effectively operate. Quality side brushes feature flexible bristles, balanced rotation systems, and secure mounting mechanisms that prevent detachment during operation. The brush design must accommodate various floor heights and surface textures while maintaining consistent contact pressure.

Durable side brush assemblies incorporate replaceable brush heads, corrosion-resistant drive mechanisms, and protective housings that shield internal components from debris infiltration. These systems must withstand repeated contact with furniture legs, wall surfaces, and floor transitions without losing effectiveness. Importers should evaluate side brush suppliers based on their ability to provide consistent brush geometry and mounting specifications across production runs.

Battery Technology and Power Management

Lithium-Ion Cell Configuration

Battery performance directly impacts both cleaning effectiveness and long-term reliability of robot vacuum systems. Premium lithium-ion batteries utilize high-quality cells with optimized chemistry formulations that deliver consistent power output through hundreds of charge cycles. The battery management system must provide accurate charge level monitoring, temperature protection, and balanced cell charging to maximize operational lifespan.

Quality battery packs incorporate multiple safety features including over-current protection, thermal monitoring, and individual cell voltage regulation. These systems prevent dangerous conditions while maximizing battery longevity and maintaining predictable performance characteristics. Importers should prioritize battery suppliers who provide comprehensive testing data and warranty coverage that aligns with expected product lifecycles.

Charging System Integration

The charging system represents a critical interface between the robot vacuum and home electrical infrastructure. Reliable charging stations feature robust electrical contacts, precise alignment mechanisms, and intelligent charging algorithms that optimize battery health. The charging base must accommodate repeated docking cycles while maintaining secure electrical connections and stable physical positioning.

Advanced charging systems incorporate safety features such as ground fault protection, overcurrent monitoring, and automatic disconnect capabilities. These systems must comply with international electrical safety standards while providing convenient user operation. Importers should verify that charging systems include adequate protection against dust, moisture, and accidental contact while maintaining reliable long-term operation.

FAQ

What are the most failure-prone components in robot vacuum systems

The most common failure points include brush bearings, wheel drive mechanisms, and filter sealing systems. These components experience the highest mechanical stress and debris exposure during normal operation. Quality suppliers implement enhanced materials and protective designs to minimize these failure modes and extend component lifecycles.

How do importers verify the quality of robot vacuum parts before committing to large orders

Successful importers typically request detailed technical specifications, material certifications, and accelerated life testing data from potential suppliers. Many also conduct third-party testing of sample components and require comprehensive warranty coverage that aligns with expected product performance standards.

Which certifications should importers prioritize when selecting robot vacuum component suppliers

Essential certifications include ISO 9001 for quality management, UL or CE marking for electrical safety, and FCC or equivalent for wireless communication components. Additional certifications such as RoHS compliance and environmental management standards indicate suppliers who prioritize regulatory compliance and quality control.

How do seasonal demand fluctuations impact robot vacuum parts sourcing strategies

Peak demand periods typically occur before major holidays and during spring cleaning seasons, requiring importers to plan inventory levels and supplier capacity well in advance. Successful importers establish flexible supplier relationships and maintain strategic inventory buffers to accommodate demand variability while minimizing carrying costs and obsolescence risks.

Table of Contents

- Essential Motor Components and Drive Systems

- Filtration Systems and Air Path Engineering

- Navigation and Sensor Technology

- Cleaning Mechanism Components

- Battery Technology and Power Management

-

FAQ

- What are the most failure-prone components in robot vacuum systems

- How do importers verify the quality of robot vacuum parts before committing to large orders

- Which certifications should importers prioritize when selecting robot vacuum component suppliers

- How do seasonal demand fluctuations impact robot vacuum parts sourcing strategies